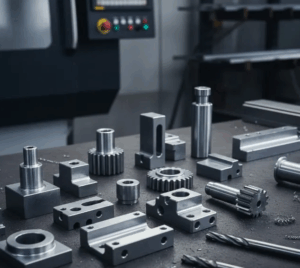

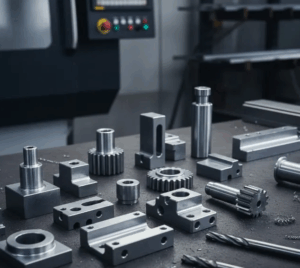

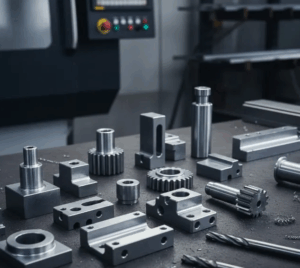

Capabilities

Our Capabilities highlight the steady, reliable strength behind every solution we provide. From precision machining to thoughtful engineering support, each service is designed to bring clarity, efficiency, and long-lasting value. We focus on grounded, sustainable practices that help your operations run smoothly, with tools and techniques that feel balanced, dependable, and built for real-world needs.

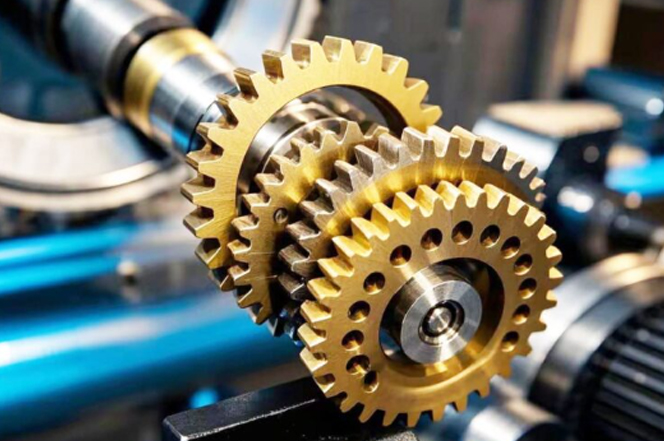

Machinery & Equipment

Our Machinery & Equipment offerings are crafted to bring steady performance and lasting reliability to your workspace. Each machine is selected with care, ensuring it supports smooth operations, balanced productivity, and long-term value. With a focus on durability and thoughtful engineering, we provide equipment that feels grounded, efficient, and ready to work quietly in the background—helping your processes flow with ease.

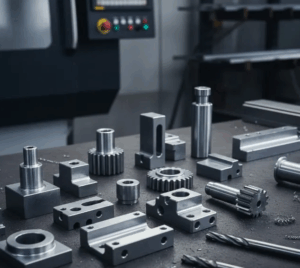

Materials

Our Materials selection is thoughtfully curated to support projects with strength, balance, and dependable quality. Each material is chosen for its natural resilience and steady performance, helping your work flow smoothly from start to finish. With an emphasis on durability and consistency, we provide resources that feel grounded and trustworthy—ready to support every step of your craftsmanship.

Value-Added Services

Our Value-Added Services are designed to bring gentle efficiency and thoughtful support to your operations. Each service adds a layer of clarity, precision, and ease, helping your workflow feel more balanced and dependable. With a focus on careful craftsmanship and long-term value, we offer enhancements that quietly strengthen your processes, making each project smoother, steadier, and naturally more efficient.

Industries Served

Our work supports a wide range of industries with steady, reliable solutions that feel grounded and thoughtfully crafted. Each sector we serve benefits from tools, materials, and services designed to bring balance, clarity, and long-lasting value. Whether it’s manufacturing, engineering, or specialized production, we offer support that fits naturally into your workflow—helping operations run smoothly and with quiet confidence.

Value-Added Services

Premium Threading

Precision Threading for Critical Connections

Expert Thread Types: UNC, UNF, Metric, NPT, BSPT & Special Forms

Advanced Techniques: Single-Point, Thread Milling, & Tap Operations

Quality Assurance: 100% Thread Verification with Thread Gauges

Material Expertise: Threading in All Metals & Engineering Plastics

Applications: High-Pressure, Aerospace, & Precision Assembly

Deep Hole Drilling

Precision Drilling for Demanding Applications

Specialized Capability: Depth-to-Diameter Ratios up to 30:1

Advanced Processes: Gun Drilling & BTA Drilling Systems

Quality Focus: Straightness & Surface Finish Control

Material Expertise: All Metals & Engineering Plastics

Applications: Hydraulic Cylinders, Mold Cooling, Aerospace & Medical

Honing & Grinding

Ultra-Precise Surface Finishing & Sizing

Precision Honing: Perfect bore geometry, size, and surface finish

Expert Grinding: Surface, cylindrical, and centerless grinding services

Tight Tolerances: Achieve critical dimensions within ±0.0001″

Superior Finishes: Surface finishes to 8 Ra and better

Quality Focus: Ideal for high-wear and sealing surfaces

Heat Treating

Enhanced Material Properties Through Precision Heat Treatment

Full Range Services: Annealing, Hardening, Tempering & Stress Relieving

Precision Control: Achieve exact hardness & material properties

Quality Assurance: Full documentation & certification available

Material Expertise: Alloy steels, tool steels & specialty metals

Applications: Wear components, tooling & structural parts

Protective Coatings & Plated Surfaces

Enhanced Protection for Superior Performance

Surface Treatments: Anodizing, Powder Coating, & Passivation

Plating Services: Zinc, Nickel, Chrome, & Cadmium

Quality Focus: Improved corrosion resistance, durability, and appearance

Material Expertise: All metals and engineered plastics

Applications: Aerospace, automotive, marine, and industrial components

NDT Testing

Quality Assurance Through Non-Destructive Testing

Testing Methods: Dye Penetrant, Magnetic Particle, Ultrasonic

Quality Focus: Detect surface and subsurface defects without part damage

Certified Processes: Meet industry standards and customer specifications

Material Expertise: All metals and critical components

Applications: Aerospace, automotive, and high-integrity parts

Industries Served

Oil & Gas

Precision Components for Extreme Environments

Specialized Parts: Valves, wellhead components, drill fittings, and pump parts

Material Expertise: High-strength alloys, corrosion-resistant metals, and specialty steels

Critical Services: Premium threading, deep hole drilling, and NDT testing

Quality Standards: API, ASME, and ISO certifications

Applications: Upstream, midstream, and downstream operations

Petrochemical

Precision Components for Corrosive & High-Pressure Environments

Critical Components: Reactor parts, heat exchanger plates, valve bodies, pump housings

Material Expertise: Stainless steels, duplex steels, nickel alloys, titanium

Specialized Services: Corrosion-resistant coatings, high-pressure threading, precision boring

Quality Focus: ASME compliance, material traceability, NDT testing

Applications: Processing equipment, piping systems, pressure vessels

Industrial Manufacturing

Your Partner for Production & Maintenance Solutions

Core Components: Gears, shafts, housings, frames, and custom fixtures

Material Expertise: Carbon steel, alloy steel, aluminum, cast iron, and plastics

Full-Service Support: Prototyping, short-run, and high-volume production

Value-Added Services: Heat treating, plating, grinding, and assembly

Applications: Machinery, automation systems, and production line support

Marine

Saltwater-Ready Components Built for Reliability

Critical Parts: Propeller shafts, rudder components, pump housings, valve systems

Material Expertise: Marine-grade stainless steel, bronze, aluminum, and corrosion-resistant alloys

Specialized Services: Precision boring, deep hole drilling, corrosion-resistant coatings

Quality Focus: Saltwater corrosion resistance, pressure integrity, classification society standards

Applications: Commercial vessels, naval systems, offshore platforms, and marine engines

OEM

Your Manufacturing Partner for Original Equipment Production

Precision Components: Housings, actuators, manifolds, and complex assemblies

Material Versatility: Metals, plastics, and exotic materials for any application

Full-Service Support: From prototyping to high-volume production

Quality & Consistency: Rigorous QA/QC with full traceability

Applications: Aerospace, automotive, medical, and industrial equipment

Industries Served - Engineering Companies

Your Strategic Manufacturing Partner for Complex Projects

Prototype to Production: Bridging the gap between design and reality

Complex Component Fabrication: Precision parts from client-supplied drawings

Material & Process Expertise: Advisory support for manufacturability (DFM)

Stringent Quality Assurance: Delivering on specified tolerances and standards

Applications: Custom machinery, R&D projects, and specialized equipment

Materials

Carbon Steel

Precision Machining for Demanding Applications

Material Specialization: Low, Medium, and High Carbon Steels (e.g., 1018, 1045, 4140)

Key Characteristics: We machine parts that require excellent strength, durability, and wear resistance.

Common Uses: Ideal for industrial components, shafts, gears, frames, and structural parts.

Full-Service Machining: Milling, Turning, Drilling, and Threading tailored to carbon steel’s properties.

Post-Processing: Ready for heat treatment, plating, painting, or other surface finishes.

Alloy Steel

High-Strength Machining for Demanding Applications

Material Specialization: 4140, 4340, 8620 & Other Alloy Grades

Key Characteristics: Precision machining of high-strength, heat-treatable steels

Common Uses: Gears, shafts, bearings, and high-stress components

Full-Service Machining: Optimized processes for tough alloy materials

Post-Processing: Expert heat treatment and finishing coordination

Stainless Steel

Corrosion-Resistant Precision Machining

Material Specialization: 303, 304, 316, 17-4PH & Other Grades

Key Characteristics: Machining corrosion-resistant, high-strength stainless alloys

Common Uses: Medical devices, food processing, marine, and chemical components

Full-Service Machining: Specialized techniques for stainless steel’s unique properties

Post-Processing: Passivation, polishing, and specialty finishes available

Aluminum

Lightweight Precision Machining Solutions

Material Specialization: 6061, 7075, 2024 & Other Aluminum Alloys

Key Characteristics: High-speed machining of lightweight, strong components

Common Uses: Aerospace parts, automotive components, enclosures, and heat sinks

Full-Service Machining: Optimized for aluminum’s machining characteristics

Post-Processing: Anodizing, painting, and specialty finishes available

Brass

Precision Machining for Excellent Machinability

Material Specialization: C360, 260, 385 & Other Brass Alloys

Key Characteristics: Superior machinability, corrosion resistance, and electrical conductivity

Common Uses: Precision fittings, electrical components, valves, and decorative parts

Full-Service Machining: High-speed production with excellent surface finishes

Post-Processing: Polishing, plating, and lacquering available

Bronze

Durable Precision for Demanding Applications

Material Specialization: 954, 932, 510 & Other Bronze Alloys

Key Characteristics: Excellent wear resistance, corrosion resistance, and low friction

Common Uses: Bushings, bearings, gears, and marine components

Full-Service Machining: Expert handling of bronze’s unique properties

Post-Processing: Precision grinding and finishing available

Copper

High-Conductivity Precision Machining

Material Specialization: C101, C110, C145 & Other Copper Alloys

Key Characteristics: Excellent electrical/thermal conductivity, corrosion resistance

Common Uses: Electrical components, heat exchangers, bus bars, and RF shielding

Full-Service Machining: Specialized techniques for copper’s soft ductile nature

Post-Processing: Plating, polishing, and anti-tarnish treatments available

Chrome

Hardened Surface Solutions for Extreme Durability

Material Specialization: Hard Chrome Plating & Chrome Alloy Machining

Key Characteristics: Extreme hardness, wear resistance, and corrosion protection

Common Uses: Hydraulic cylinders, mold surfaces, wear components, and shafts

Full-Service Machining: Precision grinding and finishing of chrome surfaces

Post-Processing: Hard chrome plating services available

Cast Iron

Precision Machining for Durable Components

Material Specialization: Gray Iron, Ductile Iron, & Other Cast Iron Alloys

Key Characteristics: Excellent vibration damping, wear resistance, and machinability

Common Uses: Engine blocks, machine bases, pump housings, and industrial components

Full-Service Machining: Optimized processes for cast iron’s unique properties

Post-Processing: Stress relieving, painting, and coating services available

Plastics, Polymers & Elastomers

Precision Machining of Engineering Plastics

Material Specialization: Delrin, Nylon, PTFE, PVC, Polycarbonate & More

Key Characteristics: Lightweight, corrosion-resistant, and electrical insulating

Common Uses: Insulators, bearings, seals, prototypes, and food-safe components

Full-Service Machining: Specialized tooling for clean, precise plastic parts

Post-Processing: Deburring, polishing, and fabrication services

Machinery & Equipment

CNC Mills with Live Tooling

Complete Parts in a Single Setup

Multi-Axis Milling & Turning

On-Machine Drilling & Tapping

Complex Contouring & Profiling

Reduced Part Handling

Faster Production Cycles

5-Axis CNC Machining

Complex Parts. Single Setup.

Simultaneous Multi-Side Machining

Complex Contours & Organic Shapes

±0.0005″ Tight Tolerance Accuracy

Reduced Fixturing & Handling

Aerospace, Automotive & Medical Grade

Engine Lathes & Turret Lathes

Classic Precision, Modern Performance

Engine Lathes: Versatile manual machining for custom jobs & repairs

Turret Lathes: Efficient repeat production of multiple identical parts

Shafts, Bushings, Cylinders & Custom Components

Expert Machinists with Decades of Experience

Ideal for Prototypes, Repairs & Specialized Production

Manual Milling Services

Precision Craftsmanship for Specialized Needs

Custom One-Off Parts & Prototypes

Precision Repairs & Modifications

Tooling & Fixture Manufacturing

Skilled Machinist Expertise

Quick-Turn Simple Projects

Production Sawing

Precision Cutting for Maximum Efficiency

High-Speed Production Sawing

Accurate Material Sizing

Metals, Plastics & Composites

Optimized for Batch Processing

Minimal Material Waste

Capabilities

CNC Milling

3-Axis: Reliable, high-precision parts.

4-Axis: Complex profiles, efficient production.

5-Axis: Intricate geometries, single setup.

Expertise in Metals & Plastics.

Rigorous Quality Assurance.

CNC Turning

Large-Capacity Precision Turning

Up to 36″ diameter × 120″ length

Heavy-duty industrial components

Aerospace, oil & gas, marine parts

Live tooling capabilities

Tight tolerance expertise

Rapid Prototyping

Fast-Track Your Ideas to Reality

3-5 Axis CNC Precision

Quick-Turn Machining

Functional Prototypes & Pre-Production Parts

Wide Material Selection

Accelerated Development Cycles

Short-Run & High-Volume Machining

Precision at Any Volume

1-1,000+ Parts

Consistent Repeatability

Optimized Production Efficiency

Rigorous Quality Control

Scalable Solutions

Secondary Operations

Precision Finishing & Detailing

Drilling: Accurate hole creation

Boring: Tight-tolerance diameter refinement

Threading: Precise internal/external threads

Grooving: Complex grooves & undercuts